fusion welding definition

A fusion welding process wherein hydrogen is dissociated in an arc struck between two tungsten electrodes afterwards recombining to supply the welding heat. The union of two metal parts by welding.

Classification Of Casting The Expendables It Cast Clint Eastwood

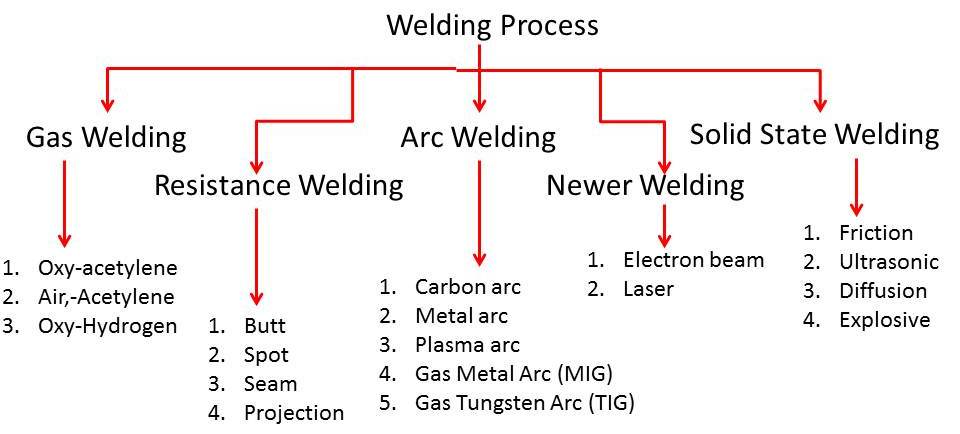

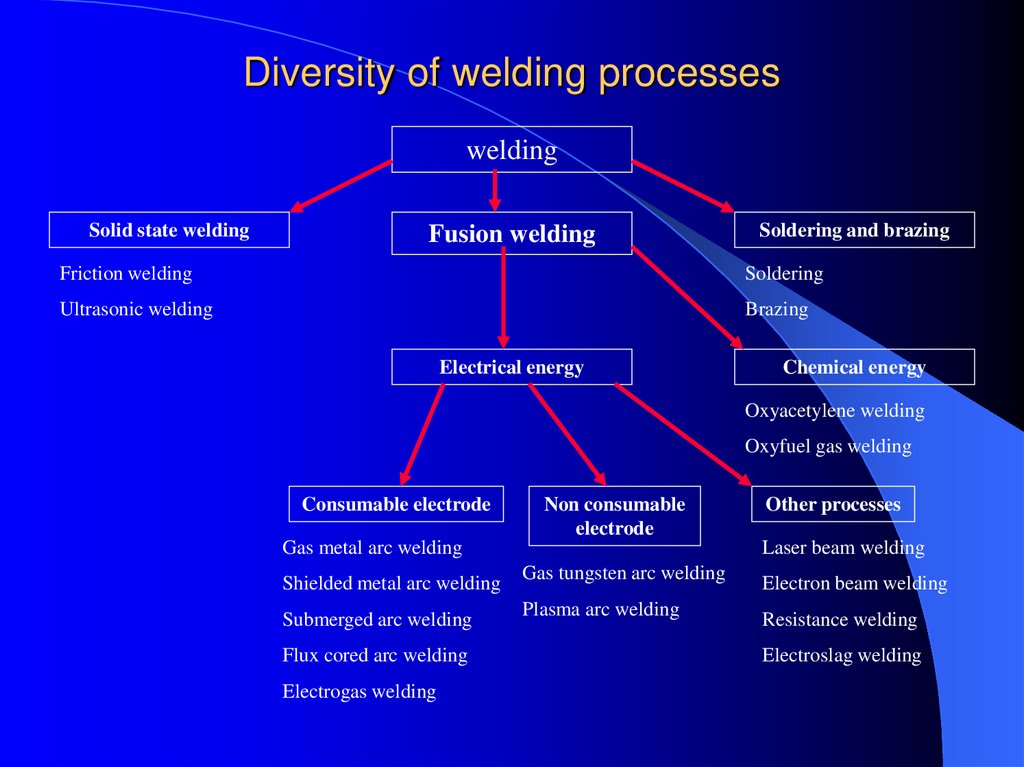

Examples of the fusion welding are arc welding gas welding resistance welding etc.

. The process requires a certain amount of heat and pressure but not necessarily an external filler material. It may appear at the edge of the parent metal or between runs. Sometimes a filler material is necessary if there are gaps in the joint you are making.

Means a process of welding metals in a molten and vaporous state without the application of mechanical pressure or blows. The lack of inter-run fusion however shows an irregular shape. Note to mention that Autogenous welding is not similar to SMAW GTAW or MIG MAG etc.

Autogenous welding is a technique of fusion welding process where welding is performed without the welding electrode or filler material. Similarly heat fusion joining for pipes and pipe fittings is a large umbrella term that contains specific procedures and methods such as electrofusion butt fusion socket fusion saddle fusion and so forth. The method may involve the use of filler material or it may not.

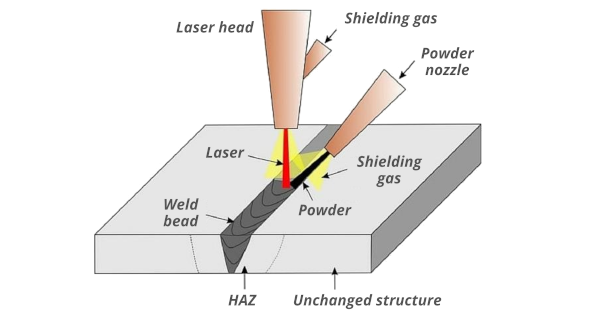

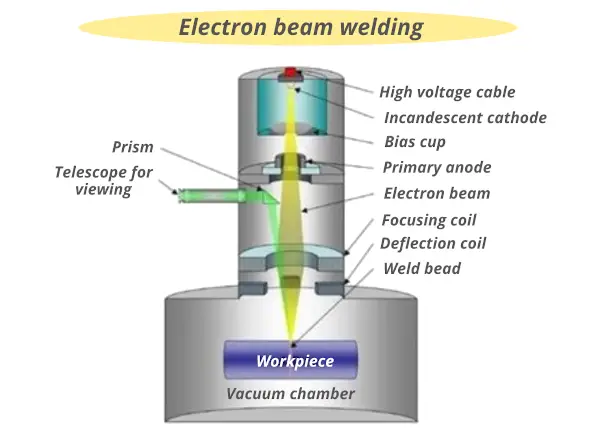

Assuming the objects are made of the same or similar materials the heat produced by a welding rig will melt their surfaces thereby allowing the objects to fuse together. Fusion welding in which the metal parts are heated until they melt together can be performed with or without the addition of filler material. Due to the high-temperature phase transitions inherent to these processes a heat-affected zone is created in the material although some techniques like beam welding often minimize this effect by introducing comparatively little heat into the workpiece.

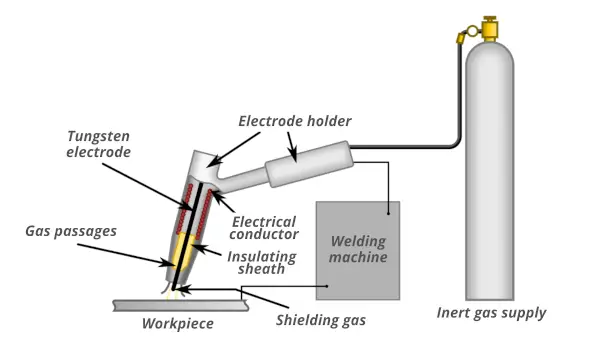

Arc welding electron beam welding and laser welding belong to this category of welding processes see also Section 30521. But instead it is one of the techniques of the existing fusion welding processes. From the definition fusion welding joins edges of different materials by heating them to a melting point.

The fusion welding process may or may not require the use of filler material for welding. So heat is always associated with these processes. To join metals by applying heat sometimes with pressure and sometimes with an intermediate or filler metal having a high melting point.

The lack of fusion is a planar defect. A definition for fusion welding is as a generic term for welding processes that rely on melting as part of joining materials of similar melting points and composition. The main difference between these welding processes concerns the distribution of heat and filler.

Fusion welding is used in the manufacture of many everyday items including airplanes cars and structures. Fusion welding processes are all those welding processes where faying surfaces of parent part as well as filler material melt down during welding for weld bead formation. Definition of fusion welding.

By melting of parent material if the joint is produced called as Fusion Welding Process. The process of fusing one metal to another using combustible gas covered electrode arcs and gas-shielded arcs. Welding is usually used on metals and thermoplastics but can also be used on wood.

The materials will undergo many phase transitions because the heating process creates a heat-affected zone HAZ on the materials. The weld pool produced is difficult to control and the heat affected zone HAZ of such welds has a relatively coarse grain adversely affecting the mechanical. The completed welded joint may be referred to as a weldment.

Welding exposes welders to gases metal fumes and toxins and increases risk of lung cancer and mesothelioma. Due to the high-temperature phase transitions inherent to these processes a heat-affected zone is created in the material755 although some techniques like beam welding often minimize this effect by introducing comparatively little. To be capable of being welded.

Smithells Metals Reference Book Eighth Edition 2004. Outside pressure application is not needed for fusion welding processes with the exception of resistance welding where significant contact pressure is necessary for the sound. Fusion welding is a generic term for welding processes that rely on melting to join materials of similar compositions and melting points.

Like other welding processes its used to join two or more objects using heat. To bring into close association or union. The lack of fusion is usually to be found at the weld inside.

Solid-state joining processes such as. 2012 Farlex Inc. Fusion welding is a process that uses heat to join or fuse two or more materials by heating them to melting point.

Fusion welding is a method of welding that involves the melting of the base metal at the joint and the joining together of the molten metals to form a weld. The American Welding Society AWS defines fusion as The melting together of filler metal and base metal substrate or of base metal only which results in coalescence ANSI AWS A30 Standard Welding Terms and Definitions. Fusion welding is a generic term for welding processes that rely on melting to join materials of similar compositions and melting points.

The welding process in which two workpieces are joined under a pressure providing an intimate contact between them and at a temperature essentially. Fusion welding is unique however because of its ability to fuse the respective objects. What is fusion welding.

Welding is a fabrication process whereby two or more parts are fused together by means of heat pressure or both forming a join as the parts cool. External application of pressure is not required for fusion welding processes except for resistance welding where substantial contact pressure is required during welding for sound joining. By using a heat source with sufficient power it is possible to fuse through a complete section of very thick plate.

Some materials require the use of specific processes. The lack of fusion between the parent metal and the weld metal shows a flat face. The welding of metals in a molten state without mechanical pressure or pounding.

Fusion welding is a method that makes use of heat to combine or fuse two or more materials into a melting point by heating them. The process may or may not require the use a filler material.

Difference Between Fusion Welding And Non Fusion Welding

What Is Radiant Energy Welding 2 Types You Should Know

Types Of Welding Tri State Fabricators

Welding Processes A Brief History Of Welding Late

Welding Tools Shielded Metal Arc Welding Gas Metal Arc Welding Arc Welding

How To Calculate Welding Joint Strength Extrudesign Types Of Welding Machine Design Joint

What Is Radiant Energy Welding 2 Types You Should Know

Welding Processes Classification Extrudesign Welding Process Electric Arc Welding Plasma Welding

Welding Process Prezentaciya Onlajn

Pin On Soyer Srm Technology En

What Is Welding Its 22 Different Types You Should Know

What Is The Difference Between Fission Welding And Fusion Welding Quora

Fusion Welding Process An Overview Sciencedirect Topics

Gas Metal Arc Welding Gmaw Welding Technology Gas Metal Arc Welding Welding Technology Welding

Welding Processes Classification Extrudesign Welding Process Machine Design Welding

Manufacturing Processes Different Fusion Welding Processes Welding Tips Gtaw Tig Welding

Welding Of Plastic Weld World Plastic Welding Welding Ultrasonic Welding

Welding Processes Classification Extrudesign Welding Process Welding Gas Electric Arc Welding

Chapter 30 Fusion Welding Processes Manufacturing Engineering Technology

0 Response to "fusion welding definition"

Post a Comment